Material and technical base

The chair has good material base, completely providing with a laboratory practical work all studied disciplines. There are laboratory and research stands as leading manufacturing firms of the electrotechnical equipment on chair . And made by forces of teaching structure and students.

- Educational station of continuous processes

The educational station of Festo firm consists of two tanks filled with the distilled water, connected among themselves and other knots tubes with latches, the pump, the heater, a receiver, the automatic poster and sensors: level gage, flowmeter, thermocouple and other elements.

The main installation is connected to the SIEMENS firm controler. The controler plays a role visualization tools and managements of parameters of operated sizes.

By means of the interface of the program it is possible to watch the transients happening in contours of regulation of temperature, pressure, an expense and level. It is possible to carry out a task of necessary size, to configure an entrance and a controler exit.

The choice of operating modes is made by change of the corresponding settings of the software.

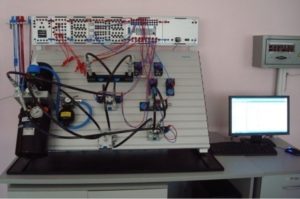

- “Pneumoautomatic and pneumoelectroautomatic equipment”

Laboratory installation represents the aluminum panel on which elements of pneumoautomatic equipment and Festo firm pneumoelectroautomatic equipment fasten. For work of system the compressor is used.

The subsystem of processing of signals in electric system receives a feed from an electric network via the power unit executed in the separate case.

Modeling of various systems pneumo – and pneumoelectroautomatic equipment is carried out on the personal computer by means of the special FluidSim-P (Demo-Version) program.

Studying of this program gives acquisition of skills at design of schemes of automated management by processes with use of elements of pneumatics.

- Laboratory complex “Hydroautomatics and Electrohydroautomatic Equipment”

The stand represents the aluminum panel on which elements of hydroautomatic equipment and Festo firm electrohydroautomatic equipment fasten. For creation of the closed hydraulic system the hydraulic pump is used. All system is filled with the oil, being under pressure.

The subsystem of processing of signals in electrohydraulic system receives a feed from an electric network via the power unit, being in the separate case.

Modeling of various schemes (systems) of hydroautomatic equipment and electrohydroautomatic equipment is carried out by means of the special FluidSim-N program on the personal computer. The library of ready elements of hydroautomatic equipment and electrohydroautomatic equipment is thus used.

Work at this stand gives the chance of acquisition of skills design of schemes of automated management by technological processes with use of elements of hydraulics.

- Laboratory of technical means of automation.

There are 4 test stands in laboratory at which students get acquainted with the equipment installed at stands, define errors and a variation of technological devices: ampermeters, voltmeters, wattmeters, manometrical thermometers and other equipment (machine guns, relay, contactors, resistance).

On the performed work students do calculations for schemes of experiments, make tables of measurements with a conclusion on the carried-out tests.

The chair has four computer classes equipped with various programs for design and implementation of schemes in the electric drive, in automation systems. Computer classes are equipped with interactive boards and have access to the Internet.

For the period of 50 years Karaganda Industrial University, founded in 1963, has become one of the leading higher ...

For the period of 50 years Karaganda Industrial University, founded in 1963, has become one of the leading higher ...